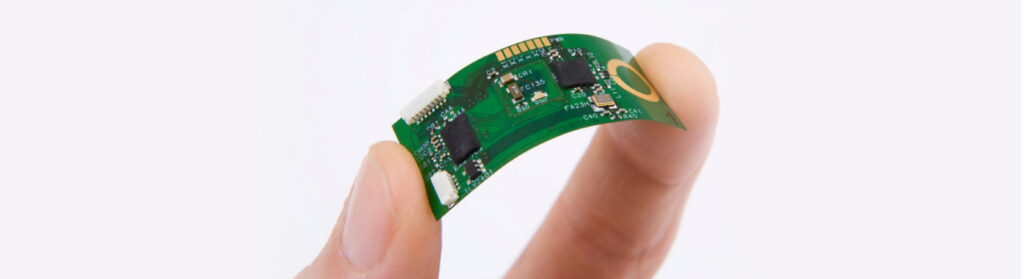

Flexible PCBs

From prototype to manufacturing, MCL has you covered for all your flexible PCB and rigid-flex PCB needs. Our knowledge and experience manufacturing flexible printed circuit boards give us a competitive edge in the PCB industry. We also require no minimum product amounts on orders and always promise a competitive price and unbeatable customer service.

Capabilities

We offer numerous customer service capabilities and board layout options, so you’ll be able to find a model that meets your products’ needs:

- Quick Turn

- Prototype Quantities

- Production Quantities

- 1 – 44 Layers

- 35:1 Drill Aspect Ratio

- Maximum Panel Size – 24″ x 30″

- Blind / Buried Vias. and Micro Vias

- Via In Pad with Fill Options

- Conductive, Non-Conductive

- Controlled Impedance

Specs and Tolerances

| Outer Layer Trace / Space | .002″ / .002″ |

| Inner Layer Trace / Space | .002′ / .002′ |

| Minimum Drilled Hole | .002″ |

| Standard Drilled Hole | .008″ |

| Drill Aspect Ratio | 35:1 |

| Minimum Pad Size | .004″ |

| Minimum Feature to Edge | .010″ |

| Minimum Core Thickness | .001″ |

| Controlled Depth Drilling | YES |

| Sequential Lamination | YES |

Flex PCB Benefits

There are some pretty amazing benefits to using flexible PCBs. Some of the advantages of flexible PCBs include the following:

- Reduced Space and Weight: Most of the advantages associated with flexible PCBs come from their low volume and weight. In fact, using a flexible PCB instead of a rigid PCB can result in a space reduction of over 50 percent and a weight reduction of 95 percent, while simultaneously maintaining the function and reliability of the circuit.

- Durability: The flexibility, reduced weight and reduced number of interconnects in the PCB allows them to handle changing external forces and improve their resistance to shock and vibration.

- Signal Integrity: Flexible PCBs work in a wide range of environments, so signals will continue to perform smoothly despite exterior conditions. This improves the PCB’s signal reliability.

- Higher Density: The thin flex layers and smaller parts mean that flexible PCBs are capable of supporting higher circuit densities.

- Minimized Errors: Due to the elimination of mechanical connectors and reduced variations in assembly methods, flexible PCBs experience reduced wiring errors.

- Low Cost: Because of the fewer assembly steps involved in the creation of flexible PCBs, they tend to be relatively low-cost.

- Heat Dissipation: The thinner flex PCB materials allow for a greater surface-area-to-volume ratio, improving heat dissipation.

Materials for Flex Circuits

Flexible circuits come in single-sided, double-sided and multi-layered forms, each of which requires a variety of materials to function. The materials that MCL works with include branded materials from trusted suppliers. A few of the flex PCB materials you can choose from include these:

- Adhesives: The requirements of an application, as well as the dimensions of the conductor involved, tend to guide adhesive selection. Some of the most popular adhesives on the market include acrylics, epoxies, pressure-sensitive adhesives (PSAs) and adhesive-free base materials.

- Finishes: You can choose from a variety of final finishes to meet the requirements of your project. A few of the finishes you can choose from include ENIG, HASL, Pb-free HASL, immersion silver, and immersion tin, and even organic materials. Each option creates different results and is best suited to different applications, so be sure to consult with MCL on the best finish for your needs.

- Insulators: Insulators are a must, and you’ll need the right insulating material to support your flexible PCB application. The wrong insulator might result in PCB failure in the long term. PCB insulators combine coverlay materials and flexible substrates in a variety of form factors and thicknesses. Some of the most used insulators include flexible solder masks, photo imageable coverlays, polyester, polyethylene naphthalate (PEN), polyethylene terephthalate (PET), polyimides, screen-printed dielectric insulators and solder masks.

We recommend you contact us directly in order to determine the best material for your PCB needs. Below are a few more options for you to consider ahead of making that call.

Advanced Features

The flex circuit market has continued to expand. With that expansion, advances in the technology have grown as well, including the following:

- Graphic Overlays: Graphic overlays are acrylic or polyester covers for PCBs that provide a type of user interface with the circuit underneath. These overlays often include LEDs, LCDs and switches, which allow the user to interact with the PCB in the desired fashion.

- Hot Bar Solder: A hot bar solder connection is an alternative to a standard connection, eliminating the need for a connector between a hardboard and flex circuit. The result is a more efficient and durable connection that is less expensive.

- Laser Skived Slots and Holes: In the past, razors were used to cut flex circuits, and the success of this process was dependent upon the person cutting the lines. With modern lasers, however, lines can be cut with extreme precision and control, resulting in even finer circuit designs in flexible PCBs.

- Panelization: This process involves assembling PCBs in large panels of multiple units. It can expedite the flex circuit assembly process substantially, especially in “pick-and-place” assembly lines. Once the units are assembled, all you need to do is break the groups apart.

- Pressure-Sensitive Adhesives: Called PSAs for short, pressure-sensitive adhesives are used by removing a protective liner and pressing an object into the adhesive to secure it. This material is often used in PCB applications to secure a portion of a circuit in place without soldering.

- Shielding: Electromagnetic interference has historically been a problem, especially in applications where electronics are particularly sensitive to interference. Improved shielding technology has made this less of an issue in recent years, reducing noise and controlling signal line impedance.

- Stiffeners: FR4 and polyamide stiffeners are often added to flex circuits in areas where the circuit may need more support, such as connection areas. This improves the strength and longevity of the circuit.

Engineering Services

The advantages of working with MCL for PCBs extend far beyond the cutting edge specs, tolerances and advanced features of our boards. We are proud to provide several engineering services to help your business meet its quality and performance needs:

- Design for Manufacturability: Our design-for-manufacturability (DFM) capabilities mean we can engineer PCB solutions that optimize every manufacturing step from fabrication to assembly to testing and delivery. Taking advantage of these capabilities means you’ll get quality, reliable PCBs quickly and be able to ensure client satisfaction.

- Design Rule Check: Our design rule check (DRC) capabilities also mean we can double-check each chip layout to ensure it abides by the necessary parameters and design rules. Our strategic manufacturing partners will be better able to maximize the use of space, and you’ll receive high-quality boards that perform well in their intended applications.

- Controlled Impedance Modeling: When your business requires controlled impedance in its PCBs, we can perform controlled impedance modeling and then adjust the copper thickness and the physical relationships between the board components as needed. That way, we ensure high-quality boards that can run between 100 MHz and 3 GHz range.

- Panelization: PCB panelization, which arranges several individual PCBs is into a single unified panel, is often a critical engineering step because it increases accuracy during automated assembly and helps ensure quality boards. At MCL, we offer panelization for anything from traditional rectangular PCBs to polygons and other more intricate designs.

- DFX-to-Gerber Conversions: Some businesses have DFX files that computer-aided design (CAD) programs have generated for them. If your company has DFX files, you’ll likely need a way to convert them to more standard, flexible and efficient Gerber files. MCL can convert your files easily to provide you with faster delivery times and minimize production errors.

Flex PCB Applications

A flex PCB is essentially the same thing as a non-flex board except the flexible PCB uses a flexible base material to make its circuit connections. This is most helpful for products that will likely not be stationary devices. The durability and size of flexible PCBs, as well as the shrinking sizes of electronics, have resulted in their adoption by a growing number of industries. Just a few of these industries and applications include the following:

- Automobiles: With the automotive industry increasingly turning toward electronic components, circuits that can handle the vibrations and stresses of a vehicle’s interior are more important than ever. A flexible printed circuit board offers a valuable option for the industry, providing a durable yet cost-effective option.

- Consumer Electronics: Flexible PCBs are typically used in small electronic products like cell phones, tablets, cameras, video recorders and other similar smaller gadgets on the market today. These products may be transported or handled regularly, making the flexible PCB’s resistance to shock and vibration a useful feature.

- High-Speed Digital, RF and Microwave Applications: The reliability of flexible PCBs makes them ideal for handling high-frequency signals.

- Industrial: Industrial electronics often handle massive amounts of vibration and stress, so flexible PCBs with shock absorption and anti-vibration capabilities are a must.

- LED: LED lighting is massively popular today in both residential and commercial applications. This is primarily because of LED technology’s incredible power efficiency. Heat is often the only concern, which can be mitigated with a flexible printed circuit board and its effective heat transfer properties.

- Medical Systems: Small and dense electronic designs are becoming increasingly important in the medical industry, with handheld surgical technology and even electronic implants growing in popularity. Flexible PCBs can be applied in both cases, meeting the durability and size requirements of surgical technology and the necessary flexing ability for implants.

- Power Electronics: Another benefit of a flexible printed circuit board is that it can be coupled with highly flexible, thin layers of copper, which means the board can handle heavier power currents. This is especially important in devices that will require more power to operate at full capacity, like those found in the power electronics industry.

Flex printed circuit boards can address most of the issues facing today’s engineers. If you’re looking for an improved stretch, broader flexibility and simple use with leading packaging changes, it’s time to talk to us about flex PCBs. Whether you need single-sided flex boards or multi-layer boards, we ensure your finished product will be of the highest quality.

From Files to Finish – Your Go-To Flex PCB Expert

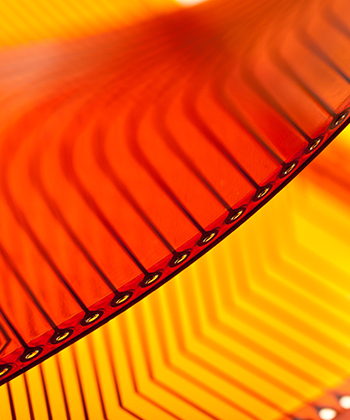

Types of Flexible Circuits

As your leading flexible PCB supplier, MCL offers you some of the most robust flexible circuit designs on the market. There are eight main types of flex circuits, from single to multi-layer options, that can also include more rigid designs. Here is a brief overview of the main flexible circuit options:

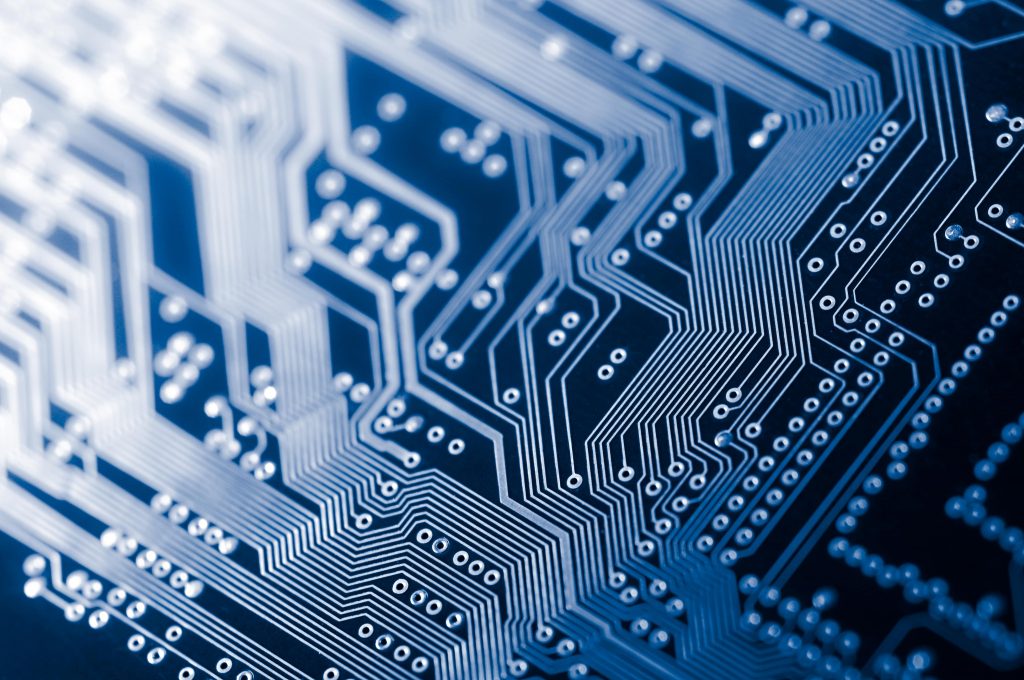

- Single-Sided Flexible Circuits: This design includes a single conductive copper layer that can be bonded between two layers of insulation or built with one polyimide insulating layer and an uncovered side. The interior copper layer then goes through a chemical etching process, producing the circuit design. The design of a single-sided flexible printed circuit board supports the inclusion of components, connectors, pins and stiffeners.

- Single-Sided Flex Circuits with Dual Access: Some single-sided flex PCBs have a dual-access design that allows you to access the conductive material from both sides of the circuit. This design function requires a flexible PCB and specialized layers to create access for the single copper layer through the polyimide layer of the base material.

- Double-Sided Flex Circuits: A double-sided flexible printed circuit board features two conductive layers with a layer of polyimide insulation between them. The conductive layer’s outer sides can either be exposed or have covers, like a copper pad. Layers are connected typically by plated through-holes, but other methods can be used. Like the single-sided flexible circuits, the double-sided flexible PCBs can support additional elements such as pins, connectors and stiffeners.

- Multi-Layered Flex Circuits: Going beyond the single- and double-sided flex circuit is the multi-layered flexible PCBs. These circuits combine multiple single- and double-sided circuits, connecting three or more flexible conductive layers with insulating layers between each. Outer layers for these units typically have covers, while a copper-plated through-hole often runs through the entire thickness of these flexible circuits. Multi-layered flexible circuits are the best solution to get around crossovers, crosstalk and impedance and shielding requirements. There are multiple design options for multi-layered circuits — for example, like FR4, multi-layered flex boards can be built using blind and buried vias. Additionally, the layers of a multi-layered circuit might be continuously laminated for added protection, though this step is usually skipped if flexibility is the highest priority.

- Rigid-Flexible Circuits: Rigid-flexible circuits have a slightly different design than those listed above and tend to cost more than other flexible PCB options, but they serve a similar purpose to that of most other PCBs. These models tend to use two or more conductive layers, but the insulation material sandwiching each conductive element can be either a rigid or flexible insulation. They’re differentiated from multi-layered circuits because they feature conductors on rigid layers, offering greater strength than similar units that only rely on stiffeners. This has made rigid-flex PCBs particularly desirable in military and aerospace industries.

- Aluminum Flexible Circuits: Flexible aluminum PCBs are optimal for high-powered industries such as medical and automotive industries, as well as those that require substantial power and lighting usage. Their tight, compact design also lets them fit easily into minuscule spaces. Their aluminum layers give them useful heat-transferring properties, and they are lightweight, durable and cost-effective.

- Microcircuits: Flexible PCB microcircuits are optimal for small consumer electronic devices. Their shock-resistant and vibration-resistant properties make them superior choices for consumer electronics, as does their exceptionally light weight. Microcircuits also provide strong signal integrity, so their minuscule size doesn’t compromise their technological performance.

- HDI Flexible Circuits: High-density interconnector (HDI) boards contain one of the fastest-growing technologies in the PCB industry. They have higher wiring densities than conventional circuit boards, so they can enhance electrical performance and speed while reducing equipment weight and size. They are ideal for consumer products like computers, phones and game consoles.

- Ultra-Thin Flexible Circuits: Ultra-thin flexible printed circuit boards have small, thin board features and materials. They are ideal in applications that call for exceptionally lightweight boards, such as portable electronics and implantable medical devices.

Our circuit boards are all certified to official IPC standards:

- IPC 6013 Type 1:This single-sided model is flexible and allows for numerous bending cycles. It is extremely cost-effective, so it can work with all varieties of budgets.

- IPC 6013 Type 2: This double-sided circuit model is even more flexible than type 1 above. Being double-sided also helps it save space.

- IPC 6013 Type 3: This multi-layered design allows for a more compact design than those of the two models above. It also offers superior flexibility, so it is ideal in 3D applications.

- IPC 6013 Type 4: This rigid-flex model features a stable platform for components, stiffeners and more. It is optimal for 3D constructions as well. It offers the benefits of boosted signal integrity, enhanced reliability and superior noise reduction. It is exceptionally lightweight, and it takes up very little space, and it allows engineers improved creative freedom in their designs.

As you can see, flex PCBs are not limited to single-sided designs — MCL can produce double-sided and even multi-layered flexible PCBs for your more complex layouts, providing you with a greater range of possibilities in connections compared to typical FR4 circuit board designs. Contact us to speak with a Customer Concierge about which type of design is best suited for your particular application.

In summary, flexible PCBs use a flexible base material to make their circuit connections. There are eight main types of flex circuits, from single- to double-sided and multi-layer options, that can also include more rigid designs. The durability and size of flexible PCBs, as well as the shrinking sizes of electronics, has resulted in their adoption by a growing number of industries, including LED, medical, power systems, and more.

Prototype Services

MCL offers in-house prototyping services. Our team has the knowledge and tools necessary to work along side our customers, to be an extension of their design team for new products. MCL routinely provides insight and works with our customer’s engineers with the goal of cost-effective design for manufacturability in mind. Our team is able to work through PCB material selection, impedance modeling, cost consulting, and manufacturing technology to help get your product launched on-time and within budget.

Whether you need single FR4 boards, rigid-flex multi-layered boards or anything in between, our team can deliver a quality prototype PCB to test and modify as needed before committing to production volumes with us.

Learn more about the benefits and applications of rapid PCB protoyping.

Contact MCL for Your High-Quality Flex PCB

Let MCL function as your flexible printed circuit board expert and partner!

As one of the most capable and experienced PCB suppliers in the United States. From our custom ERP, to our strictly controlled processes to ensure the utmost quality, to our relationships with our manufacturing partners and long list of capabilities, MCL is the company you want to partner with for something so important as your printed circuit board needs.

Be sure to browse the other technologies we offer besides flexible PCBs, including metal core PCBs, heavy copper boards and our capabilities.

Whether you need commercial or industrial PCBs, our team of PCB experts is here to help. MCL builds relationships from files to finish. Please contact MCL today to discuss your upcoming project. Call us at 717-558-5975 or contact us online.

To get started working with MCL, contact us today to request a quote

More Resources On Flexible & Rigid-Flex PCBs