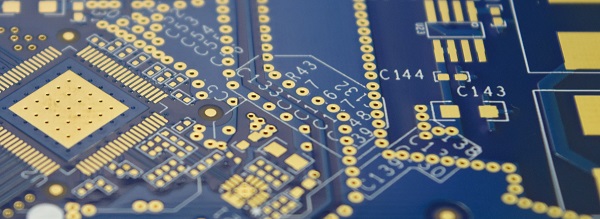

PCB Surface Finish Types

Printed circuit boards (PCB) are made of copper to ensure electric currents flow efficiently. These metals require appropriate protection from the elements to avoid oxidation and other corrosion. A range of finish types provide different levels of protection against deterioration. They also aid in certain use, such as with soldering. Various circuit board finishes are available, from options that are affordable and easy-to-apply to expensive or difficult-to-manage finishes used in only the most advanced applications.

Immersion Gold (ENIG)

Electroless Nickel Immersion Gold is one of the most popular and widely-used circuit board finishes available today. Constructed with two layers of coating, ENIG places 2-4 μ” Au over 120-200 μ” Ni. The gold protects the nickel from corrosion and the nickel protects the base metal board and allows for circuits to be securely soldered to its surface.

Advantages: flat surface to solder to, lead free and RoHS Compliant, longer shelf life, tighter tolerances can be held for plated holes.

Disadvantages: expensive, signal loss for signal integrity applications, black pad.

Immersion Silver

Immersion Silver (IAg) is applied directly to the base metal of a PCB via chemical displacement. It’s a more affordable option than ENIG, and it is also RoHS-compliant. A typical thickness for Immersion Silver is 4-12u”. Due to the way copper and silver interact, they eventually diffuse into one another.

Advantages: flat surface to solder to, lead-free and RoHS compliant, tighter tolerances can be held for plated holes, low loss for signal integrity applications.

Disadvantages: handling the PCB can cause soldering issues, it is more cost effective than ENIG but less cost effective than Immersion Tin, and the finish can tarnish and oxidize.

Immersion Tin

Immersion Tin (ISn) is applied directly to the base metal of a PCB via chemical displacement. It’s a more affordable option than ENIG and Immersion Silver, and it is also RoHS-compliant. A typical thickness for Immersion Tin is 20-50u”. Due to the way tin and copper interact, they eventually diffuse into one another.

Advantages: flat surface to solder to, lead-free and RoHS compliant, tighter tolerances can be held for plated holes and is a popular choice for press fit applications.

Disadvantages: handling the PCB can cause damage and soldering issues, tin whiskers, shorter shelf life than ENIG.

HASL

Hot Air Solder Leveling or HASL is an affordable finishing option that utilizes tin/lead to creating a thin protective covering on a PCB. Hot air bursts are used to clear excess lead or tin from the board’s surface. Formerly the industry standard, HASL popularity has faltered due to potential RoHS compliance issues.

Advantages: low cost, long shelf life, and HASL is reworkable.

Disadvantages: uneven surface for soldering, contains lead (Not RoHS Compliant), cannot hold tight tolerances on plated holes.

Pb-Free HASL

Non-toxic and more environmentally-friendly PCB finish types are gaining popularity due to concerns behind the use of lead in manufacturing. Pb-Free HAL finishes use tin or copper paired with nickel to create a protective coating. Pb-Free HASL has the same advantages and disadvantages as HASL except Pb-FREE HASL is RoHS compliant.

OSP

A PCB surface finish comparison based on green appeal leaves no questions. The Organic Solderability Preservative (OSP) doesn’t introduce any toxins into the process. Instead, an organic compound is used that bonds naturally with copper, creating an organometallic layer that protects against corrosion.

Advantages: flat surface for soldering, RoHS Compliant and lead-free, cost effective.

Disadvantages: short shelf life, handling the PCB can cause soldering issues, thickness isn’t measurable.

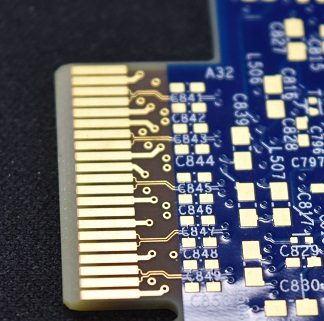

Hard Gold

Among the most expensive PCB surface finish, hard gold applications are extremely durable and enjoy a long shelf life. They’re commonly reserved for components that expect to get a substantial amount of use, with normal thickness rates ranging from 30 μin gold over 100 μin nickel to 50 μin gold over 100 μin nickel. It’s not often used for soldering points, due to poor solderability. Hard gold is typically used for edge connectors, battery contacts, and some test boards.

Advantages to Hard Gold: durable surface, lead-free and RoHS Complaint, and long shelf life.

Disadvantages: extremely expensive compared to other finishes, bus plating can be required, and additional labor required.

ENEPIG

Electroless nickel electroless palladium immersion gold (ENEPIG) is another alternative for the surface coating of a PCB — it uses multiple layers to create a universal finish that can work with numerous applications, such as soldering or wire bonding with gold, aluminum and copper. ENEPIG is one of the more optimum choices for wire bonding as well as most PCB applications.

The order of the layers over the substrate corresponds to the name of this surface finish. Over a copper base is an electroless nickel layer. Atop that layer goes an electroless palladium coating. The palladium prevents the nickel from passing through to the gold layer on top. The final coating, an immersion gold layer, keeps the palladium from interacting with environmental contaminants that could otherwise impede soldering.

ENEPIG printed circuit boards were popular many years ago due to their overall board support and are now rising once again thanks to a significant decrease in the cost of palladium. The design has been shown to successfully operate in conjunction with lead-free and eutectic solder alloys as well as most assembly processes.

ENEPIG vs. Other Finishes

ENEPIG is often referred to as a “universal” finish because it can be used for almost any PCB and in all assembly processes. Palladium completely dissolves during soldering so there is no oxide present in the nickel surface. This means your application has less probability of errors, and you can safely use it with varying solder applications.

Compared to other finishes, ENEPIG printed circuit boards will have a greater solder joint strength and are more likely to meet your industry requirements for overall PCB life and durability.

The advantages and disadvantages of ENEPIG are:

Advantages: The gold surface layer protects the PCB from tarnish and corrosion. The use of multiple layers inhibits corrosion from metal diffusion. Additionally, the composition of this finish provides a lead-free surface with a high solder strength while offering a more cost-effective option compared to electroless gold or electrolytic nickel gold. Lower contact resistance – The electrical resistance of this finish is uniform due to its production process and creates a situation where amperage is easier to predict and manage. Other advantages include:

- Pore-free finish.

- Significantly higher bond pull strength. High pull weights are maintained through multiple tests, making it especially suited to gold ball and aluminum wedge bonding.

- Strong solderability thanks to nickel protecting and reducing copper dissolution.

- Supports conductive adhesives for applications that do not need or may be harmed by solder.

- Won’t tarnish, extending its useful life.

And perhaps the best news of all is that the ENEPIG process tends to provide significant savings over electrolytic nickel gold and electroless nickel or electroless gold.

Disadvantage: Due to the inclusion of palladium and gold, both precious metals, this surface finish may not be as cost-effective as options that do not use these materials. Additionally, the application of the multiple layers must follow careful procedures for success and good solderability.