From implantable devices to next-generation wearables, engineers face mounting pressure to deliver miniaturized, high-reliability electronics that can endure life-critical environments. Traditional rigid PCBs, while proven, often limit flexibility and space optimization. Enter Rigid-Flex technology — a hybrid design that merges the mechanical strength of rigid boards with the adaptability of flexible circuits.

This white paper explores how Rigid-Flex PCBs are powering the future of medical electronics, enabling smaller footprints, higher reliability, and greater design freedom — while meeting the stringent requirements of the medical industry.

Why Rigid-Flex is Reshaping Medical Device Design

Smaller Devices, Bigger Performance

Medical innovation increasingly depends on miniaturization. Diagnostic wearables, implantable devices, and handheld instruments all require compact yet complex circuit architectures.

Rigid-Flex allows multiple rigid sections to be connected with flexible layers, eliminating cables and connectors — the two most common points of mechanical and electrical failure.

Engineering Advantages:

- Reduced size and weight

- Improved signal integrity through direct interconnects

- Enhanced mechanical stability under vibration and motion

- Simplified assembly and sterilization

- Longer product lifespan due to reduced interconnect fatigue

“Every bend and transition in a Rigid-Flex board carries mechanical consequences.

Understanding strain distribution early in design determines long-term reliability.”

Meeting Medical-Grade Demands

In life-critical systems, reliability isn’t optional.

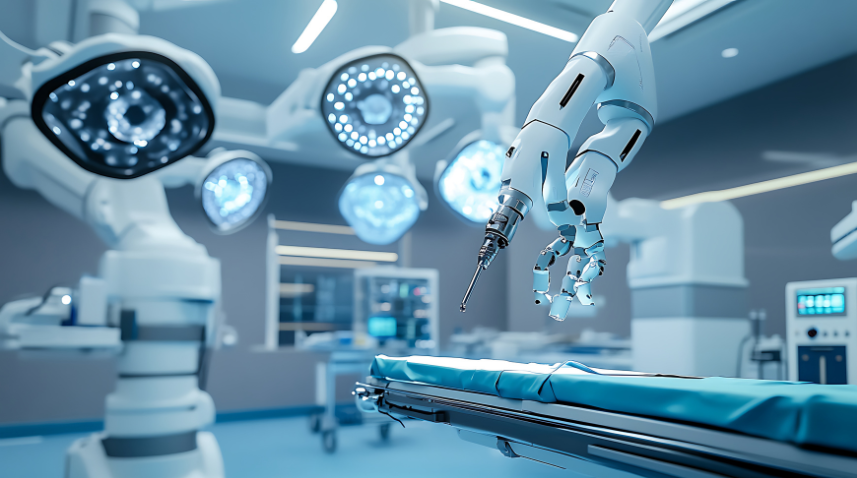

Rigid-Flex PCBs enable secure interconnects, controlled impedance, and low-noise signal transmission — crucial for devices like:

- Implantable stimulators and monitors

- Portable imaging and diagnostic units

- Wearable sensors and infusion systems

- Robotic surgical tools

Each application demands a balance of mechanical flexibility, biocompatible materials, and DFM-driven design to meet Class II and III medical standards.

Materials, Reliability & Design Collaboration

Advanced Materials for Advanced Medicine

To perform in sterilization cycles, fluid exposure, or prolonged body contact, Rigid-Flex boards must be engineered with the right materials:

- Polyimide flex cores for durability and flexibility

- Adhesiveless laminates for cleaner transitions and tighter bends

- ENIG or ENEPIG finishes for corrosion resistance and fine-pitch reliability

- Low-Dk dielectrics for high-speed signal integrity

Designers must consider controlled bend radii, staggered vias, and reinforcement zones to avoid stress cracks and delamination.

Reliability, Cleanliness, and Traceability

MCL’s medical builds adhere to:

- IPC-6013 Class 3 and ISO 13485 manufacturing standards

- Full traceability of materials and production batches

- Environmental and mechanical stress testing

- Cleanroom-level contamination control

Early Collaboration = Reliable Outcomes

The most successful medical devices are born from early collaboration between PCB engineers and manufacturers.

When fabricators are involved at the concept stage, issues like flex-rigid transition stress, via reliability, and manufacturability can be solved before prototype release — reducing time to market and risk of regulatory delays.

“In medical electronics, failure is not an option. Collaboration from design to production is the strongest form of quality control.”

Looking Ahead

Rigid-Flex designs will continue evolving with:

- Integrated DSPs and SoCs for real-time analytics

- Biocompatible and stretchable substrates

- Embedded sensors and shielding for wireless power transfer

- Sustainable materials for single-use devices

MCL continues to partner with medical innovators worldwide to turn these possibilities into production-ready solutions.

MCL specializes in design for manufacturability on complex PCB needs such as rigid-flex and miniaturization. We have evaluated and validated the necessary requirements and vendors for successful rigid-flex projects. Rely on MCL for the technical expertise and necessary preparedness to decide what options are best for your next product.

If you’re currently working on a PCB project for the medical industry, send us a visual pdf footprint for a free technical review from our team.

Don’t have it? Let us create it for you.

For more information, contact the team at MCL today!