Changing the Way Products Are Delivered to Market – MCL’s Rapid Launch Process

Rapid turnaround time for complex printed circuit boards can keep a project on schedule. Waiting 3-4 weeks for delivery of quality PCBs – the industry average – often won’t meet business needs. Issues like these can be devastating to businesses, leading to significant delays, lost contracts, and irreparable harm to a company’s reputation. MCL’s Rapid Launch Process alleviates pain points for businesses.

Providing a quick turnaround time for a quote is imperative when customers face short deadlines for product launches. When customers contact MCL for a board design quote that’s highly complex, the MCL technical team leaps into action. They quickly meet with the design team, review pertinent files and offer several manufacturing recommendations on the various options.

Once the customer approves the design, MCL provides a quote the same day. MCL offers its expertise on the best design option. Another of MCL’s clients, a contract manufacturer, faced a compressed schedule to prototype and ramp production. With the prospect of a line down, they faced the obstacle of urgently needed PCBs. MCL’s standard Rapid Launch Process delivered the needed boards on time to the customer. MCL’s streamlined process ensures an easy transition from prototype to production, saving the customer critical time and money for their consumers.

The Rapid Launch Process isn’t an additional expense or a perk for just a select group of MCL’s customers. All of MCL’s clients go through the Rapid Launch Process.

While all companies can benefit from the quicker turnaround time and technical expertise provided by MCL’s Rapid Launch Process, it is even more invaluable when businesses run into roadblocks on projects that require complex and quality PCBs quickly. Some common reasons companies need an increase speed to market for boards include:

- Quick turnaround for a new product launch date.

- Short timeline compounded by a complex issue that requires technical expertise.

- Technical expertise is needed outside a company’s current capabilities.

MCL’s Rapid Launch Process – Increasing Speed to Market

For companies that face issues delivering quality PCBs quickly, a 3-4-week turnaround jeopardizes the project’s success. MCL’s Rapid Launch Process provides a standard quick turnaround time of three to five days from start of manufacturing to delivery. Finding a company that supplies bare printed circuit boards in just a few days can relieve these pain points.

With a range of capabilities, materials, and configurations, you’ll receive a PCB built to spec with maximum quality and consistency – but with a vastly quicker speed to market than the industry average. MCL delivers even the most complex prototypes that meet your required specifications.

Through the Rapid Launch Process, MCL has delivered 11.3 million circuit boards over the last 12 months to customers across the globe with an average on-time delivery rate of 97 percent. MCL’s average delivery time across the industry, regardless of timeframe, was well above the industry average in 2021. Out of the 97 percent of circuit boards delivered on time, 99.6 percent were delivered defect-free.

Customer Success Story: MCL will do whatever it takes to meet a customer’s deadline through this agile approach. For example, ETA-USA, a custom design and manufacturer of high-quality, switching power supplies located in CA, contacted MCL when it needed a supplier that could source a specific material and build the bare boards in a very tight timeline. During the manufacturing process, ETA-USA realized it needed an even faster turnaround on the product. MCL’s technical experts worked weekends to guarantee the product met this revised deadline. The project was split into two-part numbers with separate delivery dates. MCL delivered both numbers early, despite needing to update the design of the boards in the second wave. MCL’s Customer Concierge team was in constant communication with ETA-USA during the process.

MCL’s technical expertise from prototype through production has increased speed to market by 19.8% – a game-changer in the printed circuit board industry. The Rapid Launch Process has revolutionized how hundreds of MCL’s customers navigate complex issues to meet project demands and goals.

How MCL’s Rapid Launch Process Works

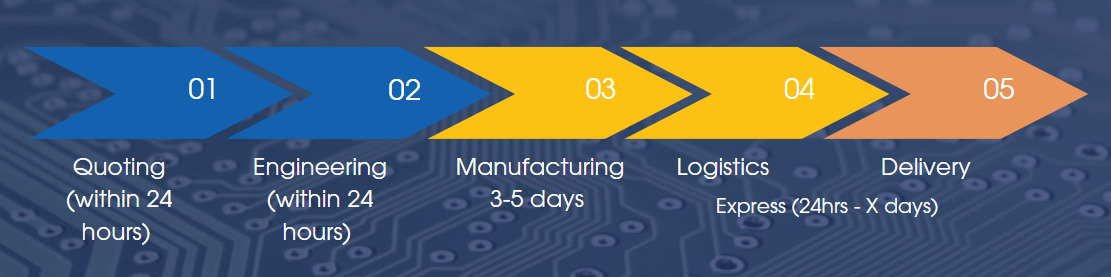

MCL’s Rapid Launch Process is a four-step process that includes quoting, engineering, manufacturing, and logistics. MCL effectively communicates with your company throughout the entirety of the project to ensure a successful outcome.

1. QUOTING

MCL’s dedicated Customer Concierge team works with each client to understand their requirements to ensure every order is right from the start. They communicate with clients every step of the way and offer value-engineering initiatives. One-third of the data packs MCL receives contain elements or features that need clarification. MCL’s technical experts work to sort out any issues to help customers achieve the best, most cost-effective design for prototype and volume production. Once MCL has all the technical specifications, they draft a quote within 24 hours. Oftentimes, MCL exceeds its own standards and provides quotes within the same day.

2. ENGINEERING

MCL’s technical experts are trained in designing for manufacturability. They are focused on evaluating each design to ensure it is optimized for volume production while at the same time providing a design that meets prototype requirements to eliminate the trouble and time of significant redesign when transitioning from prototype to production. MCL puts every project through a 56 Point Design for Manufacturing (DFM) inspection checklist. This checklist evaluates design efficiencies for manufacturing including minimum trace and space, minimum hole size and aspect ratio, layer stackup distribution and impedance concerns. Within 24 hours of the PO, MCL’s technical team will return any engineering questions back to clients.

3. MANUFACTURING

MCL has long-term, strategic partnerships with its manufacturing facilities. They own the relationship between the customer and factory at a deeper level than a smaller PCB buyer could develop to expedite communication and production. They have relationships with multiple factories to ensure an uninterrupted supply chain and employ a right fit approach to manage your risk. Their customers’ PCBs are never produced by the lowest bidder out of a large pool of factories. They evaluate and utilize each factory for only the technology and volume that they can manufacture reliably to ensure they meet performance expectations and deliver the lowest total cost board.

4. LOGISTICS

Customer service is at the forefront of MCL’s Rapid Launch Process. MCL’s custom enterprise resource planning (ERP) system communicates with factories in real-time. The Customer Concierge team communicates daily with the factory and logistic teams to provide real-time updates to its customers and ensure on-time deliveries. This process proactively notifies all parties that are involved of any issues and the progress being made to fix them.

Making a Sizable Impact on PCB Speed to Market

In a rapidly changing world, many industries face faster turnaround times and tighter deadlines. Waiting 3-4 weeks for boards is no longer acceptable. To ensure you never face failure, MCL’s Rapid Launch Process provides an exceptionally fast and cost-effective solution to help companies meet tight project deadlines and launch new products on time.

Put the Rapid Launch Process to the test! Contact us for more information or get a quote today.