PCB Layout Basics

At the heart of all electronics is the printed circuit board, typically abbreviated PCB. Without a printed circuit board, your laptop, phone and other electronic devices can’t do a thing. To help illustrate the importance of the PCB layout, here’s a basic rundown.

What Are Printed Circuit Boards, Exactly?

The printed circuit board, or PCB, is sort of the spine of your electronic device. It’s the medium through which signals and power travel over lines and pads to different points. The predecessor to the PCB was point-to-point wired circuits, which were not very efficient and were prone to short circuits and other failures as the wiring aged.

When the idea of wire wrapping — creating specific connection points where gauge wire would be wrapped around a post — came along, the PCB was born. These wire-wrapped connection points were highly efficient compared to the old method. As technology marched on, this early version evolved into the silicon and integrated circuit relay connections found in PCBs today.

Get a Free Quick Quote

The PCB Base

The PCB Base is like your pizza crust. It’s typically a fiberglass board (specifically FR4), and it is the solid foundation of the PCB that makes it thick and rigid. Some more flexible PCBs can be made with a high-temperature plastic or epoxy base. These are cheaper to manufacture, but are not as durable as FR4.

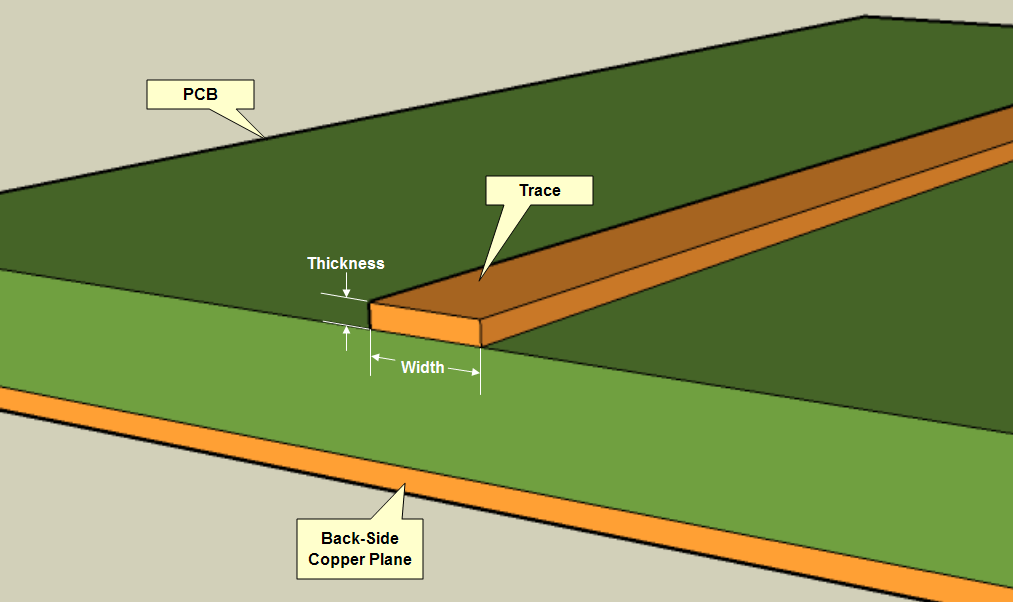

Copper Layer

The copper layer is like the sauce for your pizza. A thin copper foil layer is adhered to the board. If you have a single layer board, your copper layer is only on one side. In a double-layer board, copper is added to both sides of the base.

Solder mask Layer

The solder mask is like the cheese layer of your pizza. It goes on top of the copper layer and prevents solder jumpers by helping ensure the soldering marks are correct. The solder mask layer also insulates the copper traces so the copper does not make contact with other conductive parts of the board, and it’s what gives your board its color.

Silkscreen Layer

The silkscreen layer is like your pizza toppings. It puts the finishing touches on the PCB, adding numbers, layers and symbols to guide manufacturers during the assembly process and to indicate where each point or component is to be placed or connected.

That’s all there is to it. Your PCB is like an electronic pizza, made up of different layers to create an easily changeable platform which allows electronic circuits to communicate. To find out more about PCB layout service use and why MCL is the trusted name for PCB layout service in the United States, get in touch today.

Contact MCL Today

Our award winning customer service team is standing by to provide you with the solution you need for your PCB production and assembly project. Call us at 717-558-5975 or click here to contact us online.