Easily connect with qualified overseas and domestic partners with MCL. Our proven process and buying power allows us to act as an extension of your team to make PCB sourcing easy. Core company fundamentals such as “do the right thing, always” and “make quality personal” guide our decisions as we continuously advocate for our customers.

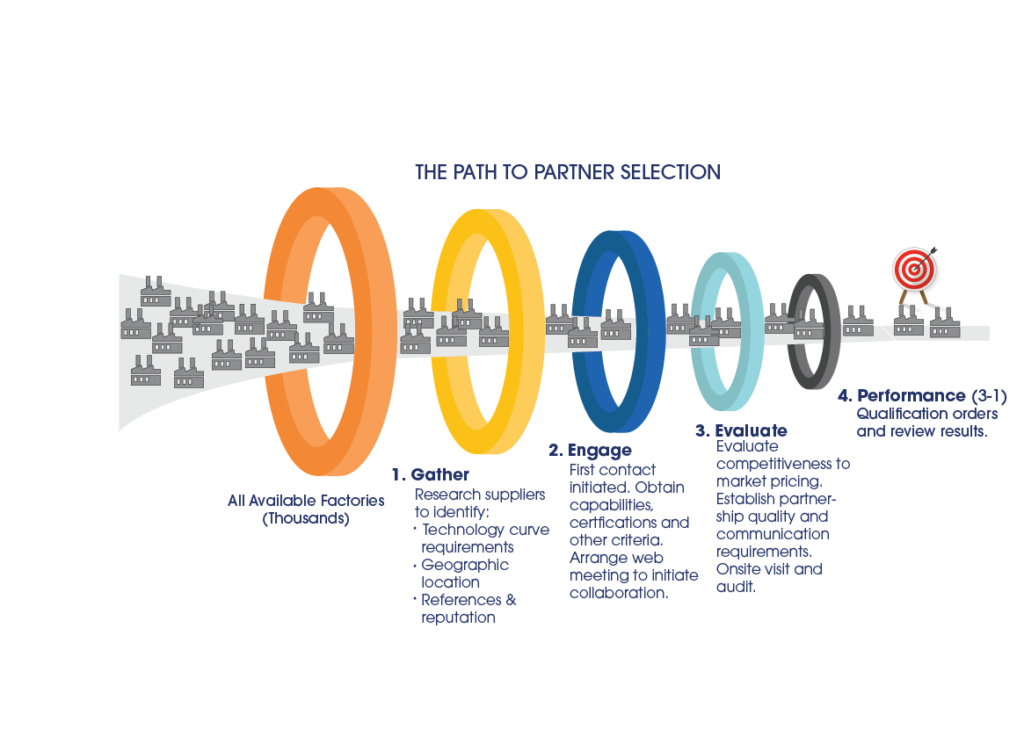

Here’s how we source the best partners for each customer’s needs while maintaining the highest reliability and quality.

Partner Selection

We employ global strategies while utilizing a local presence and a personal, hands-on approach. Our rigorous assessment and testing process allow us to continuously evaluate and develop relationships in order to select the right partners. Every circuit board is unique and has its own technology curve. We target partners whose core competencies are best suited for your boards on a part number to part number level. This helps drive higher quality and reduced lead times, resulting in better pricing.

Optimized Performance & Outcomes

We own our partner relationships at a deep level. Armed with a depth of industry knowledge, we engage our technical experts and large PCB spend to unlock superior partner performance & support. In order to build a lasting partnership where everyone wins, we work with our partners to evaluate and optimize their competencies. Our internally developed Vendor IQ evaluates and validates partner capabilities and certified competencies according to MCL Quality Standards. MCL has relationships with multiple manufacturing partners to ensure unlimited capacity and employ a right-fit approach to manage risk. Our customers’ PCBs are never produced by the lowest bidder out of a large pool of factories. We evaluate and utilize each partner for only the technology and volume that they can manufacture reliably to ensure we meet performance expectations and deliver the lowest total cost board.

Quality Management

Our Quality Management System has resulted in a 99.6% defect free product ratio for our customers. Evaluation and collaboration are our core tactics to tracking partner on-time delivery and quality. When things go wrong, and sometimes they do, we take a proactive approach following our core fundamentals to ‘deliver results’ and ‘making quality personal’. Our main focus during unforeseen issues is to maintain your supply chain’s operation while minimizing risks. MCL promptly starts a root cause analysis within 24 hours to identify and address the underlying cause, implementing corrective and preventive measures to prevent future occurrences. We ensure ongoing communication to update all involved parties on the progress and recovery efforts. This process is documented in an MCL 8D corrective action report and verified during vendor meetings.

Evaluation: When it comes to quality, we have over 100 years of combined industry experience and a fully trained staff, including a local presence overseas. In addition to utilizing the Vendor IQ to optimize vendor capabilities, we utilize a Vendor Scorecard to monitor ongoing quality and certified competencies throughout the partnership. As an ISO Certified company, we also manage a supplier database of up-to-date certifications for ISO, Automotive, Aerospace, etc.

Collaboration: We work with our partners frequently for continuous improvement to achieve mutual success. Information is exchanged on a daily, weekly, monthly and quarterly basis.

Daily: Projects, logistics, delivery timeframes, and customer complaints.

Weekly: Quality metrics, report including customer complaints, defects, and on-time delivery performance.

Monthly: Pareto analysis and reason codes for on-time delivery, defects, vendor capacity and continuous improvements. We perform monthly vendor calls with domestic and overseas MCL support team members on the call.

Quarterly: Mandatory quarterly business review with an emphasis on quality and delivery